Changsha office 0731-88922097

Zhuzhou office 0731-22867780

DETAILSPAGEProduct CenterTechnical SolutionProject Case |

Particulars

In 2011, CRRC Zhongzhu Zhuji notified the bidding procurement to bid for 95 electric locomotive orders. In 2013, it also won an order for 459 electric locomotives, creating the largest order for the export of high-end rail transportation equipment to date. The car is a single-end cab. The locomotive has a track gauge of 1065mm and can operate under AC25KV/DC3KV two current systems with a maximum speed of 100km/h. The locomotive body is an overall load-bearing structure with a compression load of 4.45 MN and a tensile load of 4 MN. It adopts self-developed electric traction system, microcomputer network control system, narrow-gauge bogie, wireless data transmission system, intelligent energy management system and so on. The vehicle is equipped with an AAR-compliant air brake system and a WDP system (hard-wire power dispersion control system). South Africa's dual-flow narrow-gauge electric locomotive is China's first dual-flow AC drive export electric locomotive with independent intellectual property rights. It has filled many domestic technical gaps and also created a multi-flow electric locomotive development platform in China. Development process Project launch in October 2012 Passed the electric drive system program review in December 2012 Passed the overall technical program review in February 2013 The first car was dropped in May 2013 Completed the whole model test in July 2013 Formally launched traction operation on December 12, 2013 Key technical parameters

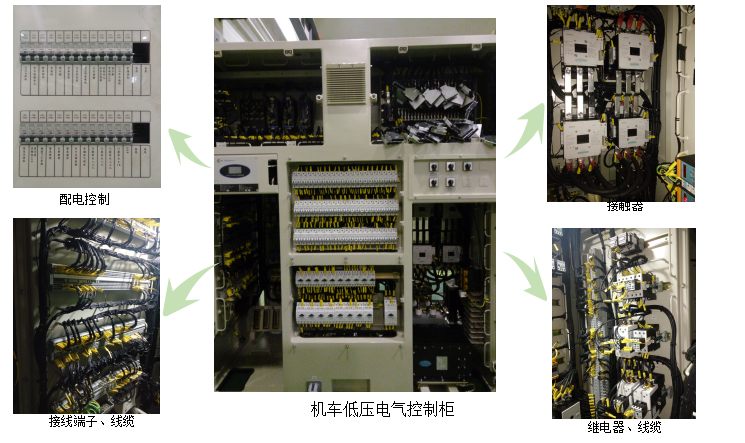

Our product advantages: Operating temperature range -40 to +70 °C According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc. Anti-vibration and shock resistance Meets the vibration and shock resistance requirements of EN50155, IEC61373; Cage spring clamping technology ensures that the product is reliably connected under vibration conditions. Low smoke, halogen free, flame retardant Meets the requirements of EN45545 (HL1 ~ HL3) fire protection standards Wide voltage range: Control voltage range from 0.7 to 1.25Us, integrated surge suppressor According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc.

|