Changsha office 0731-88922097

Zhuzhou office 0731-22867780

DETAILSPAGEProduct CenterTechnical SolutionProject Case |

Particulars

China Standard EMU refers to the EMU (the 254 important standards China standard accounts for 84%), which is dominated by the Chinese standard system. Its functional standards and supporting rail construction standards are higher than European standards and Japanese standards, with distinctive Chinese characteristics. . In the case of multiple CRHs (the four major types of introduction and China's self-designed CRH6), it is necessary to standardize (unify) the Chinese EMUs for interconnection. The standard EMU represents the current advanced standards system for the world of EMU technology. For the first time, the full autonomy of the EMU traction, braking and network control systems has been realized, which indicates that China has fully mastered the core technology of high-speed railways, and the high-speed EMU technology has achieved full autonomy. The standard EMU adopts the CR (China Railway) code, with three speed grades of CR400/300/200 and a continuous speed of 350, 250 and 160 km. Development process Project launch in June 2013 The overall technical conditions were completed in December 2013. The design of the program was completed in September 2014. Officially launched on June 30, 2015 The type test and application assessment were carried out from May 2015 to May 2016. First passenger flight on August 16, 2016

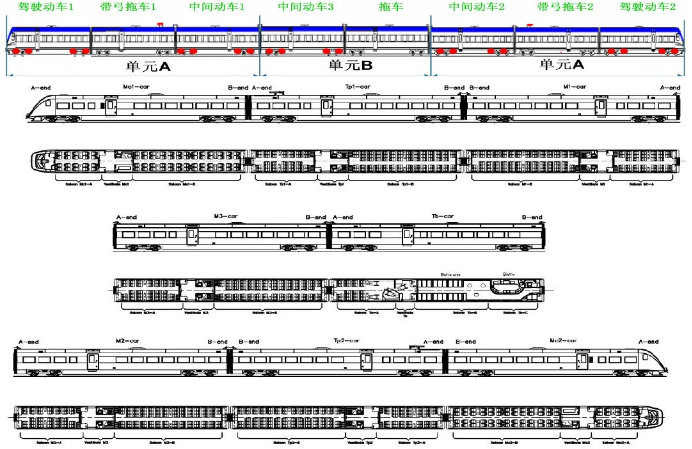

Key technical parameters The important standards adopted by China's standard EMUs cover all 13 major aspects of EMU basics, bodywork, running gear, cab layout and equipment, and traction electrical. The design of the standard EMU is combined with the actual needs of China, such as continuous high-speed operation, long distance, high density of driving, large passenger capacity, high cold, snowy, plateau sand, coastal hot and humid, haze, catkins and other conditions. , put forward the overall technical conditions of the EMU. Operating speed: 350km / h Group form: 8 groups (4 moves 4 drag) Capacity: 556 people (10 seats in business, 28 seats in first class, 518 seats in second class) • Train length: about 209m? Body width: 3360mm Car top height: 4050mm Structure layout

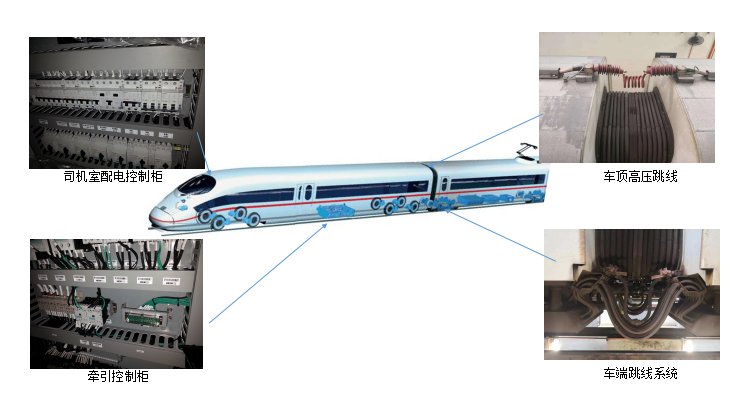

Our product advantages: Customized roof and car jumper cable solutions according to special requirements of the project Operating temperature range -40 to +70 °C According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc. Anti-vibration and shock resistance Meets the vibration and shock resistance requirements of EN50155, IEC61373; Cage spring clamping technology ensures that the product is reliably connected under vibration conditions. Low smoke, halogen free, flame retardant Meets EN45545 (HL1 ~ HL3) fire protection standards Wide voltage range: Control voltage range from 0.7 to 1.25Us, integrated surge suppressor According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc. Meet the certification of multiple international organizations such as EN, CE, UL, VDE, ROHS...

Previous: No information found

Next: No information found

|