Changsha office 0731-88922097

Zhuzhou office 0731-22867780

DETAILSPAGEProduct CenterTechnical SolutionProject Case |

Particulars

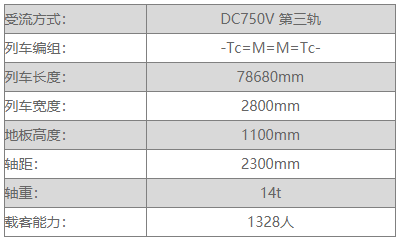

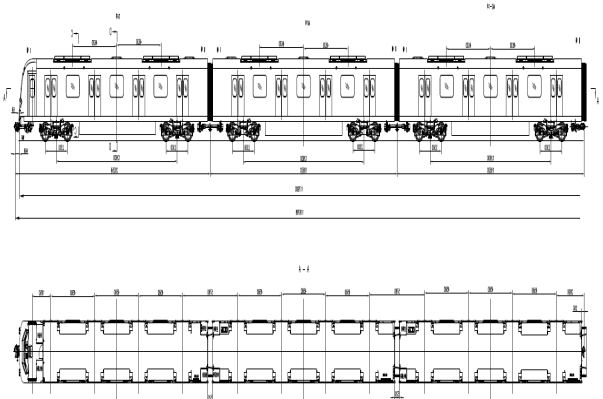

The CRRC Zhongzhu Metro Line 1 Metro B-type vehicle has a total of 35 columns, 4 moves, 2 tows, 6-segment, wide-body drum-type aluminum alloy vehicles, and the train has a top speed of 80 kilometers per hour. The train adopts all-welded aluminum alloy body technology, based on the air brake technology of tread braking, and intelligent air duct system technology. The main safety and reliability, energy saving and environmental protection, green low carbon brand, unlike the previous subway, the first use of overvoltage protection resistors in the traction braking system, to play a balanced energy feedback when the vehicle brakes. Through the technology of weight reduction and energy-saving system integration, the Zhengzhou rail transit vehicles with six sections are nearly 10 tons less than traditional rail transit vehicles, saving up to 100,000 kilowatt-hours per year. At present, the CRRC Zhongzhu machine has received train orders for several subway projects such as Line 2, Line 2, and Line 5 in Zhengzhou. Development process Signed a project contract in December 2011 Project launch in May 2012 In July 2012, passed the electric drive system program review Adopted the overall technical program review in November 2012 First train departed in May 2013 The trial operation was officially opened on December 28, 2013. Key technical parameters

The train formation map is as follows

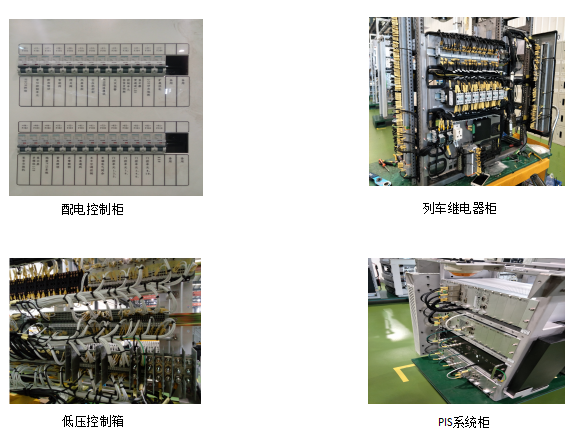

Our product advantages: Operating temperature range -40 to +70 °C According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc. Anti-vibration and shock resistance Meets the vibration and shock resistance requirements of EN50155, IEC61373; Cage spring clamping technology ensures that the product is reliably connected under vibration conditions. Low smoke, halogen free, flame retardant Meets EN45545 (HL1 ~ HL3) fire protection standards Wide voltage range: Control voltage range from 0.7 to 1.25Us, integrated surge suppressor According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc.

Previous: Kunming Metro Line 1 Project

|