Changsha office 0731-88922097

Zhuzhou office 0731-22867780

DETAILSPAGEProduct CenterTechnical SolutionProject Case |

Particulars

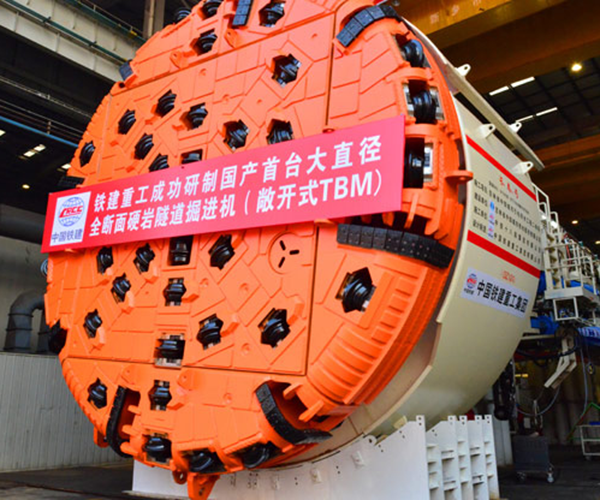

Features: - Advance drilling, advanced support, direct observation of changes in the lithology of the cave wall, is conducive to geological map depiction. - The cutter head adopts Hardox board, chrome carbide composite wear plate and peripheral hard alloy block with high wear resistance and long service life; - The main drive adopts imported double row cylindrical roller thrust bearing, which has long life and high safety factor; - Reliable and efficient PLC control system, real-time online monitoring and data acquisition. - Innovative multi-variety material conveying system, safe and efficient transportation of segments, filling materials and various construction consumables; - The mainframe structure and system layout meet the requirements for in-situ disassembly in the hole, and the equipment is easy to disassemble and transport; - Patented single-tube single-pump foam system with continuous adjustment of injection parameters and good system reliability.

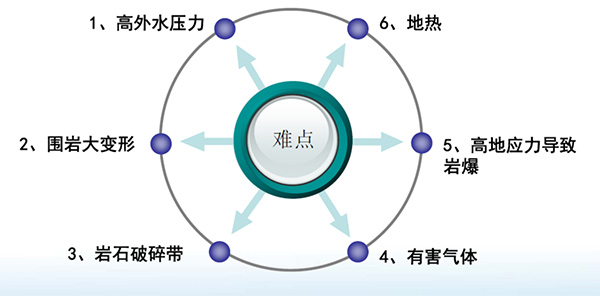

Project Name: Xinjiang ABH Water Transmission Tunnel Project Project Location: Grade IV of Xinjiang ABH Water Transmission Tunnel Project Project verview: The length of the engineering tunnel is about 42km, the excavation hole diameter is 6.53m, the designed water delivery flow is 70m3/s, and the tunnel slope is 2‰. The tunnel is mainly composed of type II and III surrounding rocks. The uniaxial compressive strength of the surrounding rock is mostly between 80 and 180 MPa. The tunnel passes through multiple fault zones, and the groundwater is developed in fault and unconformity contact zones. In addition, this TBM needs to continuously dig for about 20 kilometers, which is the longest tunnel in China's TBM. There are world-class engineering geological problems such as “large buried depth, large deformation of surrounding rock, strong rock burst, crossing large fault fracture zone, high ground temperature and rock mass alteration fracture zone”, which is the most challenging tunnel in TBM construction. .

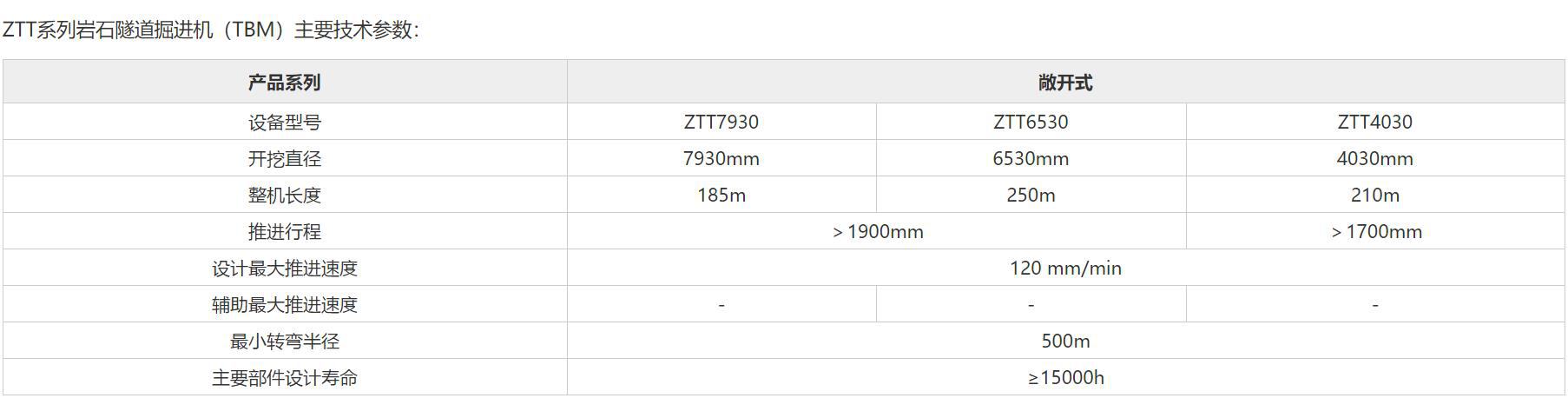

Equipment type and parameters: "large buried depth, variable diameter" inclined well open type TBM, excavation diameter 6.53m, length of the whole machine is about 250m, weight is about 1250 tons, minimum turning radius is 500m, maximum adaptation slope is ±11%, The total power is about 4700kW, of which the cutter drive power is 2800 kW, the rated torque is 4510 kN, and the maximum thrust is 2000 kN. In particular, it can work at a depth of 2,000 meters from the ground, and the diameter of the excavation can be adjusted between 6.53 meters and 6.83 meters according to the construction needs. Therefore, this TBM has a special ability of "large buried depth and variable diameter" than the general one. Innovative points: expansion technology of block cutterhead; high-efficiency rock-breaking technology for downhill excavation; long-distance stepping technology for starting downhill; synchronous lining bottom arch technology for downhill excavation; equipped with large-displacement emergency anti-slope drainage system and slag Water separation mechanism; advanced drilling system, high-efficiency material transportation system; according to engineering geological conditions, TBM is specially designed for rockburst protection, emergency drainage, long-distance tunnel ventilation, etc., to ensure the safety and stability of inclined shaft excavation High-quality, high-efficiency long-distance horizontal tunneling. Equipment users: China Railway 18th Bureau Group Co., Ltd., China Water Resources and Hydropower Third Engineering Bureau Co., Ltd.

Next: No information found

|