Changsha office 0731-88922097

Zhuzhou office 0731-22867780

DETAILSPAGEProduct CenterTechnical SolutionProject Case |

Particulars

Features: - Advance drilling, advanced support, direct observation of changes in the lithology of the cave wall, is conducive to geological map depiction. - The cutter head adopts Hardox board, chrome carbide composite wear plate and peripheral hard alloy block with high wear resistance and long service life; - The main drive adopts imported double row cylindrical roller thrust bearing, which has long life and high safety factor; - Reliable and efficient PLC control system, real-time online monitoring and data acquisition. - Innovative multi-variety material conveying system, safe and efficient transportation of segments, filling materials and various construction consumables; - The mainframe structure and system layout meet the requirements for in-situ disassembly in the hole, and the equipment is easy to disassemble and transport; - Patented single-tube single-pump foam system with continuous adjustment of injection parameters and good system reliability.

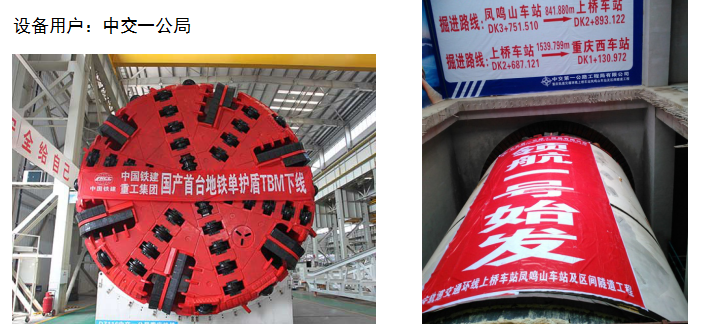

Project Name: Chongqing Rail Transit Ring Line Bridge Station, Fengmingshan Station and Interval Tunnel Project Project Location: Fengmingshan Station, Shangqiao Station, Chongqing West Railway Station Project Overview: There are 33 stations in Chongqing Rail Transit Line, with a total length of 51 kilometers. Because the geological conditions of the Chongqing metro are mainly sandy mudstone, sandstone and argillaceous siltstone, and the section tunnel of this section mainly passes through the uneven layer of soft upper and lower hard, the fracture of the rock mass is poorly developed, showing an overall block structure, medium thick and thick. The layered structure is uneven. In particular, the tunnel crosses urban roads, residential buildings, high-rise buildings, pile foundation interchanges, and local shallow covering soil, which requires high control of formation deformation. The sandstone rock mass in some sections contains calcium cement and has a large wear on the tool. Long distances through sandy mudstones, mud cakes and other phenomena. Difficulties in engineering: the tunnel passes through the uneven layer of soft and hard. The tunnel crosses urban roads, residential buildings, high-rise buildings, pile foundation interchanges, and local shallow covering soil, which requires high control of formation deformation. Downhill boring, there may be a phenomenon of seepage of surrounding rock. The sandstone content along the sandstone is high, and the natural compressive strength is also high. The sandstone rock mass in some sections contains calcium cementation, which has a large wear on the tool. Long distances through sandy mudstones, mud cakes and other phenomena. Equipment model and parameters: ZTT6880 single shield rock tunnel boring machine, excavation diameter 6880mm, total length 104 meters, total weight about 700 tons, installed power exceed 2000kW. Innovation: integrate tunnel excavation, lining, slag discharge, transportation, ventilation, drainage, dust removal and other functions. The equipment adopts a large number of versatile module designs, and at the same time reserves the interface of the earth pressure balance mode, which can be easily transformed into an earth pressure balance shield with strong versatility. In order to ensure the safety, high quality and quick completion of the project, a super-powered cutterhead drive system is also deployed, and the capacity can be expanded as needed to ensure the long-term stability and tunneling efficiency of the equipment in the hard rock formation. Construction performance: This single shield hard rock roadheader achieved the highest score of 24 meters. After expert review, Tiejian Heavy Industry has used the single shield hard rock roadheader for urban subway construction for the first time. In addition to its remarkable environmental and economic effects, it has also broadened the application field of domestic single shield hard rock roadheader. . Compared with the shield construction method, the single shield hard rock roadheader solves the problem of the original shield construction method, which pollutes the environment and is more environmentally friendly. In the construction process, the single shield hard rock roadheader has high efficiency of slag discharge. The process is simplified and the construction speed is faster. At the same time, the cost of construction materials can be reduced by about 300 yuan per meter, and the total construction cost is reduced by about 2 million yuan. Through the sandy mudstone and sandstone strata, overcome the uneven structure of soft and hard, smoothly control the stratum, and safely pass through the residential building, commercial building, and pile foundation interchange. Achieve superior performance with a maximum daily footage of 24 meters.

|