Changsha office 0731-88922097

Zhuzhou office 0731-22867780

DETAILSPAGEProduct CenterTechnical SolutionProject Case |

Particulars

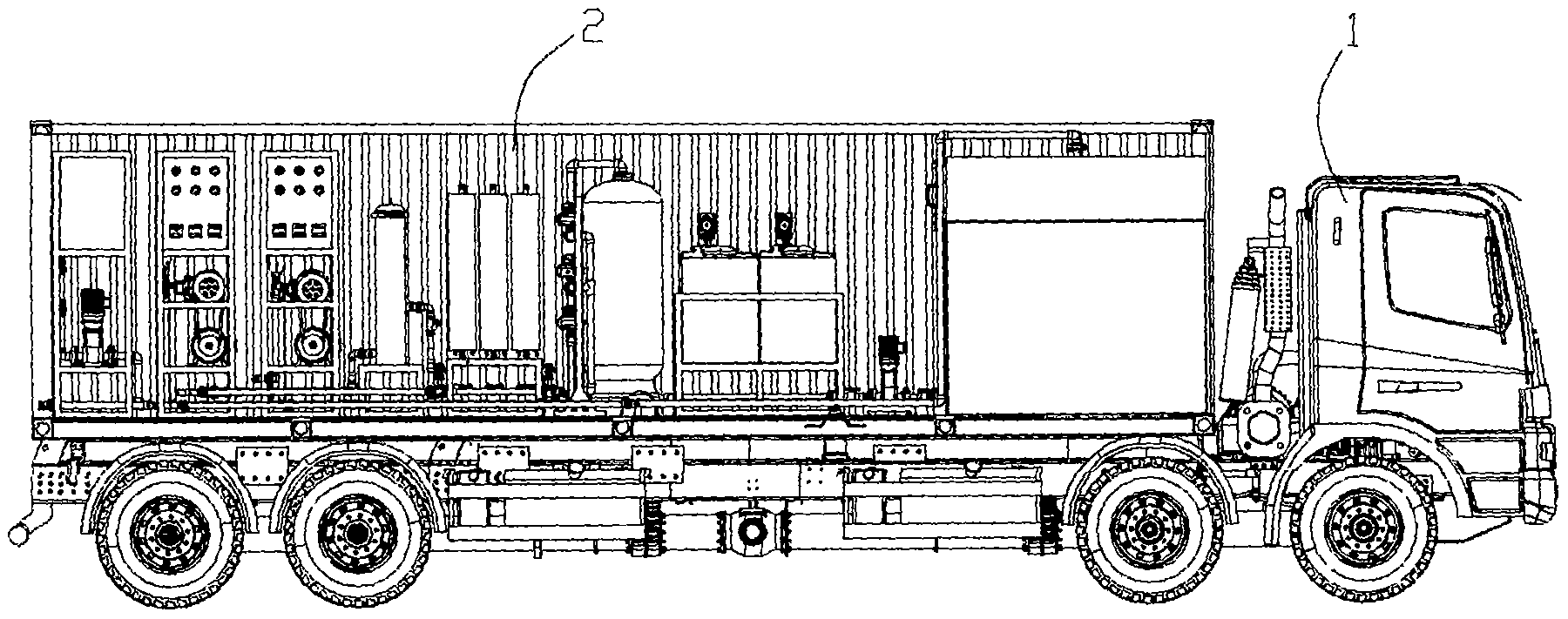

ZOOMLION sewage leachate treatment vehicle ZLJ5250TWCE4, using the world's most advanced two-stage reverse osmosis-physical separation process (DTRO) technology, the daily sewage treatment capacity can reach up to 100 tons. The vehicle is mobile and flexible, and the water treatment system is turned off at any time, which greatly reduces the cost of use. It can realize multiple landfill contiguous treatment and emergency protection of water source pollution accidents. The equipment is integrated and modularized in the factory, with few attached structures and a small footprint. It is not affected by the landfill period of the landfill, and is less affected by external factors. It does not depend on the biochemistry of the front end and can adapt to the changes in the water quality and quantity of the leachate in each period of the landfill. High degree of automation, convenient operation and maintenance: PLC control system has perfect automatic detection and self-protection functions. The equipment running status or fault can be displayed visually on the big screen, and the operation and maintenance are convenient.

Project launch in January 2014 The program was completed in August 2015, and the prototype was launched in December of the same year. From January 2016 to June 2016, the operation, type test and announcement information. Upgraded and improved in June 2018, introducing more new technologies to make it more intelligent, modular, stable and reliable Structure layout

Daily throughput: 30/50/80/100 tons Vehicle-mounted: 17910 mm* 2496 mm* 4000 mm (length * width * height) Container type: 9658 mm* 2438 mm* 2800 mm (length * width * height) Core process: two-pole reverse osmosis (DTRO) Our product advantages: 1. Quickly copy cyclic I/O data between two networks (10-15 ms) 2. Verified and testing by all PLC manufacturers 3. Ability to create web pages, display and control processes by using data from other connected devices 4, through the included OPC server, can quickly and dynamically transfer fieldbus data to SCADA/HMI/Enterprise system based on Microsoft Windows 5. Optional control and status information added to I/O data for diagnostic purposes 6, sturdy independent housing for use in harsh industrial environments Pass EMC EMC certification, EU certification, UL certification, etc.

|