Changsha office 0731-88922097

Zhuzhou office 0731-22867780

DETAILSPAGEProduct CenterTechnical SolutionProject Case |

Particulars

HXD1 locomotive is designed to improve the domestic railway transportation capacity, and also to promote the modernization of railway equipment technology. It is developed by CRRC Zhongzhou Zhuzhou Electric Locomotive Co., Ltd. combined with the experience of its DJ4 locomotive on China Daqin line. A new type of locomotive for heavy-duty freight on the main line railway. This type of locomotive is suitable for the transportation needs of the long-distance section and the long-slope ramp to haul heavy-duty and long-form marshalling freight trains. The car body adopts the central quantity bearing mode, which is convenient for modular production; the bogie adopts the low traction rod, the basic brake adopts the wheel disc brake, which effectively improves the reliability of the locomotive; the air brake adopts the CCBII brake system and the electric brake It adopts regenerative braking, energy saving and environmental protection; the locomotive has external reconnection control function and is equipped with locotrol remote reconnection control system. The driver can remotely control two heavy on-line vehicles in one driver's cab. The project has been mass-produced to 881 units so far.

Project started on March 21, 2011 Approved by the electric drive system on August 12, 2011 Adopted the overall technical program review in October 2011 The first car was dropped in February 2012 Complete vehicle type test from April to June 2012 Completed the assessment of 300,000 km of the entire vehicle from July to December 2012

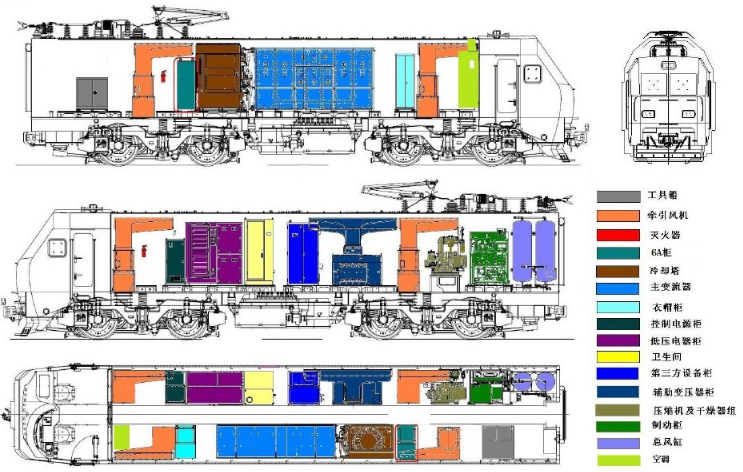

Equipment layout

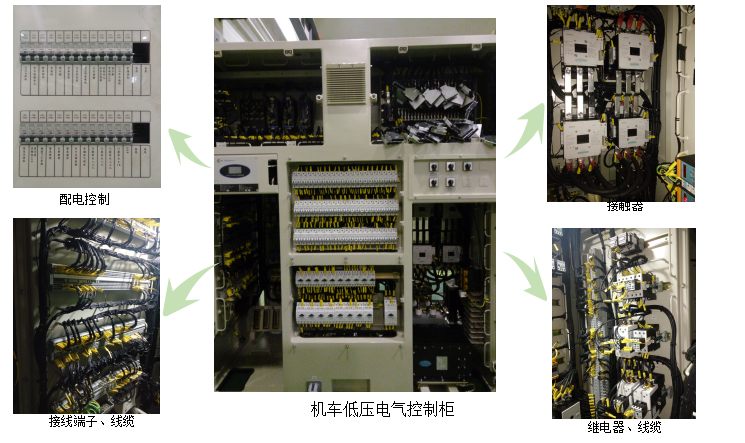

Our product advantages: Operating temperature range -40 to +70 °C According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc. Anti-vibration and shock resistance Meets the vibration and shock resistance requirements of EN50155, IEC61373; Cage spring clamping technology ensures that the product is reliably connected under vibration conditions. Low smoke, halogen free, flame retardant Meets EN45545 (HL1 ~ HL3) fire protection standards Wide voltage range: Control voltage range from 0.7 to 1.25Us, integrated surge suppressor According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc.

Previous: No information found

Next: No information found

|