Changsha office 0731-88922097

Zhuzhou office 0731-22867780

NEWSINFORMATION |

The article detailedTunnel 3d scanning -- innovation of tunnel deformation monitoring technology

Category: Company News

Date: 2018-08-04

Click: 2979

Collection:

The deformation monitoring of tunnel is of great significance to the safety of tunnel construction and operation. The traditional monitoring methods mainly use total station instrument, cross-section instrument and convergence instrument to monitor the buried points on the tunnel wall. However, these methods are not only time-consuming and laborious, but also difficult to realize the overall, real-time and automatic monitoring of the tunnel.

Traditional tunnel monitoring methods

With the improvement of measurement accuracy of 3d laser scanner, its application scope has been extended to deformation monitoring. Three-dimensional laser scanner has obvious advantages in the application of subway tunnel detection, which can effectively reduce the intensity of manual work and greatly improve the work efficiency as a non-contact measurement method. It can not only complete the collection of basic data of the original geomorphology, but also scan the tunnel in the construction or operation stage to obtain the high-precision point cloud model. Point cloud data can be directly used to intercept section data to check and analyze the quality and state of tunnel engineering. It can provide all kinds of data results, including 3d model, transverse and longitudinal section diagram, central axis extraction, over-and-under-excavation analysis diagram, and truly reflect the initial state of the tunnel after completion.

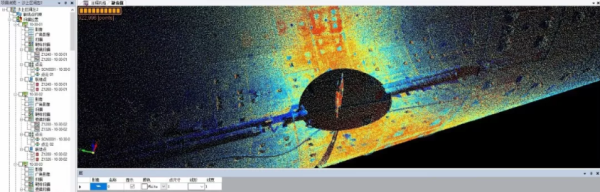

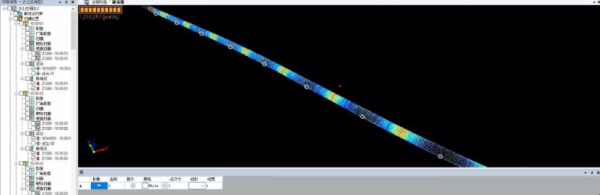

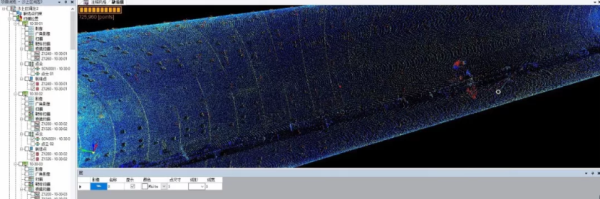

Point cloud data obtained by a 3d laser scanner

Changsha xingte general electric co., ltd. focuses on providing customers with industrial automation, intelligence, information, integrated products and technical solutions, is the track engineering equipment and underground engineering equipment intelligence and information technology leader. Relying on years of experience in underground engineering, our company has established a stable and good cooperative relationship with China railway construction, and developed digital tunnel, digital mine and other intelligent underground engineering systems. Laser scanning system can be used to provide customers with digital tunnel scanning, tunneling machine operation assistance scanning, palm laser scanning and other customized development and solutions.

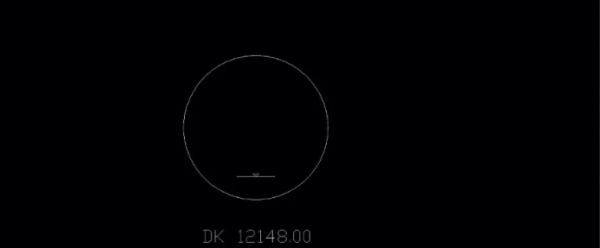

Schematic plan of the tunnel

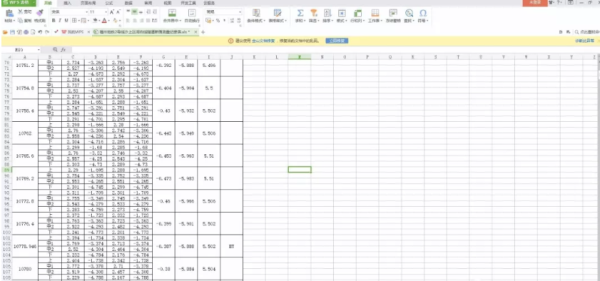

Changsha xingte technical solution In this study, only part of them were scanned and the data analysis results of a tunnel section detection were performed. The main steps are as follows: 1. Site survey, understanding of tunnel design lines, clear measurement requirements, and making operation plans.

Through the data processing of the above five steps, we successfully completed the project. Results show According to the current needs of the design unit, we need to decide the data in the specified format to be submitted by the testing unit according to the construction mode of subway tunnel.

|