Tunnel construction is a high-risk project. From the perspective of informatics, the risks are caused by the slow collection of underground dangerous rock environment information, incomplete information analysis and processing, and inadequate information sharing and utilization. Therefore, the key to the safety and efficiency of tunnel construction is to improve the information construction of the tunnel and gradually realize digitalization and intelligence.

What are digital and smart tunnels? The two are closely related but different.

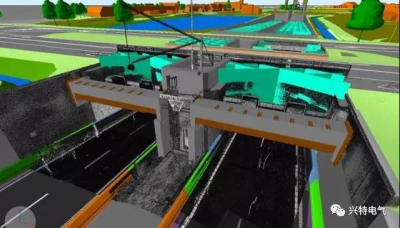

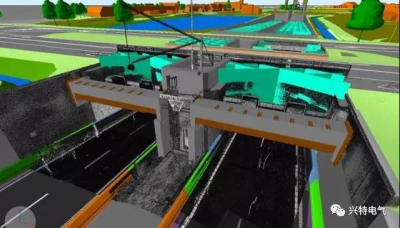

Digital tunnel is the primary stage of tunnel engineering informatization and the virtual comparison of "physical tunnel". The foundation of digital tunneling is virtual reality technology (VR) and BIM technology. Through the combination of virtual reality and BIM technology, managers and builders can more intuitively perceive the construction and operation of the building and the tunnel and its environment, as well as the collision detection, construction progress simulation, project quality analysis, safety risk prevention and control of the proposed project. Therefore, based on digital information, digital tunneling is a new tunnel technology system and production organization mode that is continuously applied in the whole process of tunnel production through digital modeling, simulation, evaluation and optimization of resources, planning, design, production and management.

What are the characteristics of digital tunneling?

(1) open system: by a series of hardware and software systems, the system between the use of open interface and standards to achieve interconnection; The system is constructed by means of overall planning and step-by-step implementation. Tailored to your needs.

(2) 3d visualization: tunnel resources and engineering 3d modeling based on real coordinates; 3d visualization of production facilities; 3d visualization of production process.

(3) visual planning and design: based on the value model, to maximize the net present value and risk control for the goal of the preparation of medium and long term production planning; Based on the engineering network, the short-term production plan is made with the goal of production balance control.

(4) production process subsystem automation and centralized control.

(5) collaborative production management: production process-oriented integrated optimization system, collaborative optimization of each production link; Comprehensively improve the overall operation level of the tunnel, completely solve the information island.

The intelligent tunnel is the extension of the digital tunnel and the intellectualization of the digital tunnel. Smart tunnel is to connect sensors and GPS units tracking moving targets with rfid units and geological advance prediction system to form the Internet of things. Cloud computing technology is used for data fusion, processing and analysis of perceived information to realize the integration of online "digital tunnel" and Internet of things. After the intelligent analysis and processing, the intelligent response and decision support instruction are made to realize the intelligent service.

There is no clear boundary between the digital tunnel and the wisdom tunnel, but rather a process of ascension and development.

The intelligent tunnel is mainly embodied in four aspects: perception, interconnection, integration and intelligent service. Use the Internet to connect all sensors, and then realize the intelligent transmission and storage of perception data. At the same time, the Internet of things and the Internet will be fully connected and integrated, and multiple data will be integrated into a set of data, which will be transmitted at any time for changes in tunnel construction and operation. Intelligent service is a system structure that USES cloud technology to provide services on the basis of big data computing, analyzes and processes massive data with big data, and provides efficient intelligent services with different levels and requirements for tunnel operation. The perception information is not only the underground perspective, but also the thorough perception. The ubiquitous intelligent sensors can realize the comprehensive and comprehensive perception of the state of tunnel construction personnel, as well as the perception of the operation state.

A real time safety risk perception system for a subway cross river communication channel was adopted to construct a multi-field coupling real time perception system for communication channel construction based on pipeline grid, so as to realize automatic continuous data collection, analysis and early warning in the whole construction cycle, including advanced geological prediction system. From the left line of the tunnel to the right line, five frozen tubes of embedded sensors were driven into the tunnel, a total of 20 sensors. The position of the deepest sensor was 10m away from the outer wall of the tube piece. The behavior of construction personnel is also very important for the safety control of construction. In addition, the safety information of environment, structure and people in the construction process of the connecting channel is integrated for safety analysis and judgment, and the early warning information is released timely and effectively.

In the comprehensive construction of subway tunnel pipelines, it is necessary to complete the installation of more than ten professional systems such as communication, signal, comprehensive monitoring, ventilation, hvac and fire protection in a very limited space. The characteristics of BIM technology, such as the digitalization and visualization of 3d model, have successfully solved the problem that cannot be solved by the original 2d plane. From the design stage, a coordinated and internally consistent computational 3d information model has been established for the construction project, which enables all participants of the project to effectively work together in the whole project cycle.

Changsha Hing special General Electric Co.Ltd

Address: room 807, chuangye building, lugu enterprise square, no.27 wenxuan road, high-tech zone, changsha, hunan

Telephone: 0731-88922097 88614760 88927559 89707759

Fax: 0731-88922440