Changsha office 0731-88922097

Zhuzhou office 0731-22867780

NEWSINFORMATION |

The article detailedChangsha xingte digital laser measurement

Category: Company News

Date: 2018-07-28

Click: 2574

Collection:

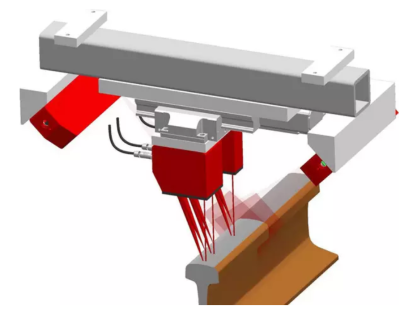

Changsha Hing special General Electric Co.Ltd focuses on providing customers with industrial automation, intelligence, information, integrated products and technical solutions, is the track engineering equipment and underground engineering equipment intelligence and information technology leader. Relying on years of experience in the rail transit industry, the company has developed a laser detection system dedicated to the intelligent operation and maintenance of rail transit by combining with domestic and foreign advanced laser technology enterprises, central south university, southwest jiaotong university, national defense university and many other domestic institutions of higher learning. For the safe operation of domestic rail transit, daily maintenance provides a strong solution. Digital laser track detection system Laser dynamic rail detection system adopts laser precision measurement technology, and its 2D and 1D laser measurement system has the comprehensive characteristics of high precision, two-dimensional detection, no scanning, anti-strong light, waterproof and dustproof, etc., which truly realizes the online high precision rail contour/abrasion/gauge/wave grinding automatic digital detection of railway rail inspection.

This non-digital laser precision measurement system is mainly used for intelligent measurement of rail contour/abrasion/gauge/corrugation. The laser measuring system is required to be of high precision, high reliability and long life.

Laser portable rail detector Changsha xing, independent research and development of laser detector is designed for portable rail track measurement and design, integrated without contact laser displacement sensor measurement technology, TFT screen computer software and orbital parameters, each measuring time less than 9 seconds, set measurement includes tracks, channel rail and fork contour at an organic whole, real-time display and store measured results CF card, can be fast to deliver data to the computer for analysis.

Technical parameters:

Tram track sander

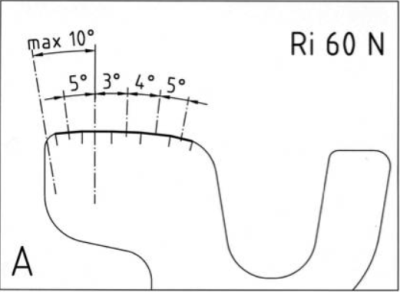

Corrugation is the small undulation on the rail head that causes the noise and wear of vehicle wheel and rail. According to the depth of wave grinding, one or two grinding cycles can be carried out per grinding. Grinding Angle and number of times depends on the shape of the rail or customer requirements (usually 5-6 times grinding). The dust produced in the grinding process will be absorbed by the dust collection system. The vacuuming power is 500m3/h. Dust is left in the pre-separator and filter bag. The spark guard has two suction channels and a guard plate to prevent sparks from flying.

Road and rail digital rail sander

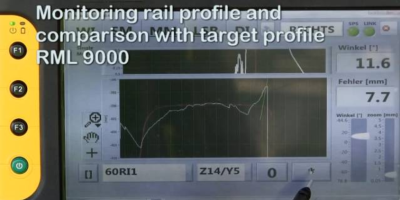

Changsha xingte united with foreign advanced laser manufacturers and domestic institutions, jointly launched small intelligent digital rail grinding and maintenance equipment and professional solutions. Among them: rail turnout laser digital detector: loaded with Swiss anti-interference highly reliable laser displacement sensor, rail turnout detection repeat accuracy up to 0.05mm, adapt to a variety of rail and high and low temperature, sunshine, rain and snow environment, provide rail and turnout full set of detection program, guide grinding, through the product and application of double authority certification.

Road and rail dual-use grinding car: it can be driven on the highway and railway at the same time, and it can reach the section of the road to be maintained quickly and conveniently. System is equipped with laser digital detection and rail grinding monitoring unit, according to the outline, real-time and high precision measurement of rail than standard rail grinding database, computer automatic recommendations of grinding operation, operators can be a key set polishing procedures, automatic rapid setting and adjust the Angle of the location, polishing, grinding, etc. It can not only polish the t-shaped rail and groove rail, but also customize the turnout area. Small intelligent digital rail grinding system has been successfully used in high-speed railway lines, ordinary lines, heavy load lines, urban rail, subway, tram, etc., small flexible, efficient intelligent grinding detection, significant cost savings, prolong the rail life. Previous: Xtek digital tunnel - smart tunnel

|