Changsha office 0731-88922097

Zhuzhou office 0731-22867780

DETAILSPAGEProduct CenterTechnical SolutionProject Case |

Particulars

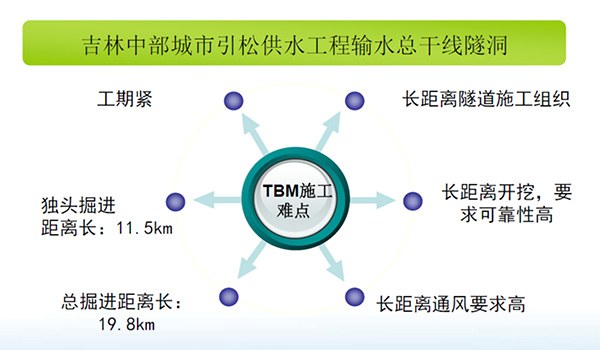

Project Name: No. II Standard for the Water Supply Project of the Central City of Jilin Province (TBM1) Project Location: Yongji County, Jilin City, Jilin Province Project Overview: The central urban water supply project in Jilin Province is the largest water transfer project in Jilin Province in history, with the longest water transmission line and the widest area of water conservancy projects. The main trunk line of the water transmission line is 371.54km long, and the total construction period of the trunk line engineering is 6 years. The TBM is located in the second section of the Fengman Reservoir from Jilin City to the left bank of the Wende River. The total length is 22,600m. The tunnel is built with an iron-built heavy-duty TBM excavation. The construction of the TBM is divided into two stages, with a total length of 19,7m, a first stage of 8298m and a second stage of 11499m. The slope of the tunnel is 1/4300, the maximum buried depth is 536.8m, the proportion of Class II surrounding rock is 32.80%, the proportion of Class III surrounding rock is 56%, and the proportion of Class IV and V surrounding rock is 11.2%. The main rocks along the line are tuff and granite. The compressive strength of the previous survey was 74-169 MPa, and the maximum measured compressive strength of the rock during the excavation process exceeded 200 MPa. Difficulties in engineering:

Equipment type and parameters: ZTT7930 open type TBM, excavation diameter of 7930mm, the whole machine length is about 185m, the whole machine weighs about 1500t, the installed power is about 5000kW, and the maximum tunneling speed exceeds 120mm/min. Innovation point: The research theory of hob wear mechanism is established through simulation analysis and engineering practice phase structure; the special tool for tool wear monitoring is developed by using two methods: wire grid and resistor row, and a new method for tool wear detection is explored; Under the vibration condition, the design method of the drive system; through the simulation analysis, solves the problem of propulsion interference of the open TBM attitude adaptive propulsion system; the technology solves the problem of the influence of vibration on the pose measurement during the open TBM construction, and verifies the wavelet The comprehensive filtering algorithm preprocesses the data of the inclinometer, which effectively improves the measurement accuracy of the inclinometer under general vibration; Construction performance: Tiejian Heavy Industry Co., Ltd. is the lead unit of the “Great Diameter Full-section Tunnel Excavation Equipment and Major Engineering Machinery Equipment” in the “Key Technology and Application of Large Diameter Hard Rock Tunnel Excavation Equipment (TBM)” of the 863 Program of the Ministry of Science and Technology. The first domestic open TBM developed by Tiejian Heavy Industry signed the TBM procurement contract in June 2014. The design and manufacturing time is only 7 months, and the transportation is 1 month. The site assembly, commissioning and stepping time are shared for 2 months. , on March 26, 2015, the smooth start of the excavation. On May 11th, the footage was 73m, and on December 23rd, 2015, the footage was 86.5m, which set a record for the highest daily footage of the domestic open TBM. In May and June, TBM was excavated in Class III surrounding rock, and the monthly footage was over 920m for two consecutive months, achieving the best results in stable tunneling of Class III and IV tuff formations. Beginning in July 2015, it entered the hard stratum of Class II granite. The maximum uniaxial compressive strength measured at the site of this section was over 200 MPa, accompanied by partial fracture zone. In July 2015, the monthly footage was 550m, the 558m in August, 509m in September, 736.5m in October, 851m in November, and 1209.8m in December. In January 2016, the first section was completed. Since the trial operation in March 2015, the total number of tunnels has been 6865m, and the average monthly footage is 725m, which is the highest in China. |