Changsha office 0731-88922097

Zhuzhou office 0731-22867780

DETAILSPAGEProduct CenterTechnical SolutionProject Case |

Particulars

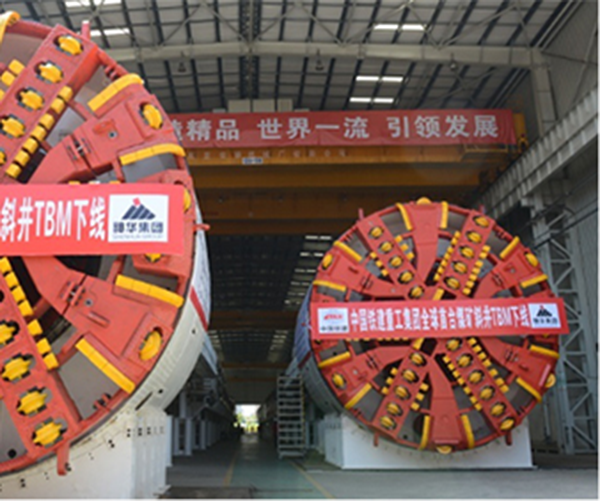

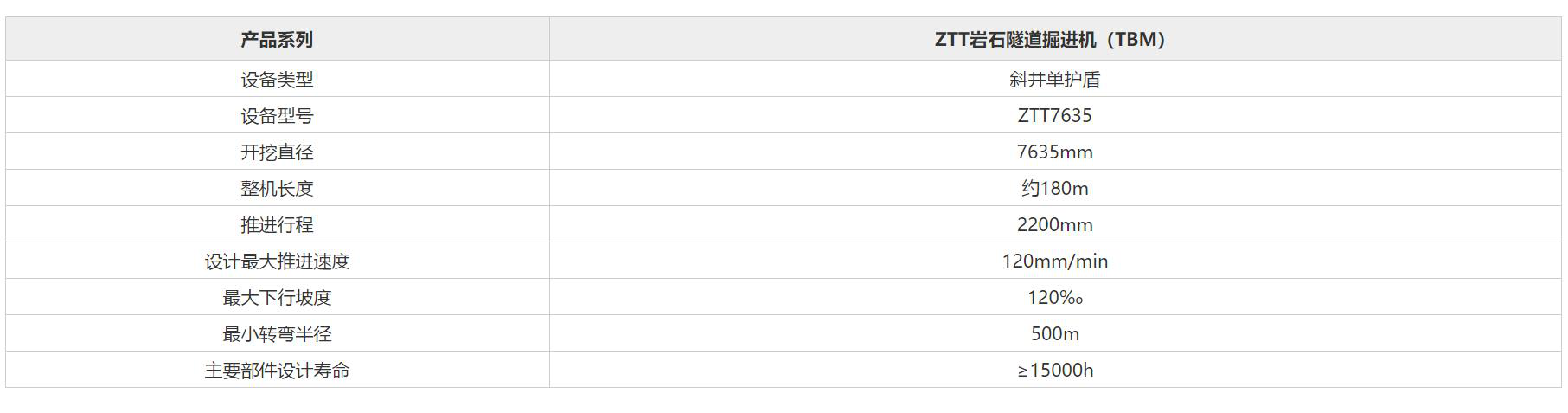

Features: - Independent research and development, with completely independent intellectual property rights; - The cutter head adopts Hardox board, chrome carbide composite wear plate and peripheral hard alloy block with high wear resistance and long service life; - The main drive adopts imported double row cylindrical roller thrust bearing, which has long life and high safety factor; - Reliable and efficient PLC control system, real-time online monitoring and data acquisition; - Innovative multi-variety material conveying system, safe and efficient transportation of segments, filling materials and various construction consumables; - The mainframe structure and system layout meet the requirements for in-situ disassembly in the hole, and the equipment is easy to disassemble and transport; - Patented single-tube single-pump foam system with continuous adjustment of injection parameters and good system reliability. Product parameters:

Project Name: Inclined Shaft Engineering of Taigemiao Coal Mine, Xinjie, Inner Mongolia Project Location: Taige Temple Mining Area, Xinjie, Erdos City Project Overview: Shenhua Xinjie Mining Area is located in Erdos City, Inner Mongolia. It is one of the key construction projects of 100 million tons of super-large coal energy base during the 12th Five-Year Plan period. It is also a demonstration project for the construction of modern mining areas with advanced technology, safe, high efficiency and green harmony. . The experimental inclined shaft is the core project for the development of the mining area. The slope of the inclined shaft is -6°, the maximum buried depth is 680m, the total length is 6500m, the average compressive strength of the rock mass is 40-60MPa, and there are local high pressure aquifer, soft rock deformation and fault fracture zone. Bad geology, the project has the difficulties of “deep burial, long down, continuous downhill, rich water and high pressure, and varied strata”. Difficulties in engineering: (1) Deep and long: The length of a single inclined well is more than 6km, and the maximum buried depth is more than 600m. It requires high construction and organization such as ventilation, drainage and material transportation. (2) Continuous downhill: The entire section of the inclined shaft is designed to have a slope of 6%, which has a great influence on the material transportation safety and the filling of the tube. (3) Water-rich high pressure: The inclined well passes through the permeable layer several times, and the maximum water inflow is expected to reach 165m3/h, which is easy to generate large head pressure, which affects the TBM tunneling and the structure of the segment. (4) Vriability of the strata: the inclined wells pass through the strata including the Cretaceous and Jurassic, of which: the Cretaceous is mainly composed of sand gravel layer, fracture zone, mudstone and sandy mudstone interbed, etc., with strong water permeability and poor self-stability; The Jurassic system partially crosses the coal-bearing strata, and there are harmful gases such as gas, which have high safety risks. Equipment Overview: This TBM has a total length of 238 meters, a total weight of more than 1,200 tons, a diameter of 7.62 meters, a minimum bending line radius of 500 meters, a total installed power of 4,900 kilowatts, and a rated torque of 8,300 kilometers. It is an excavation of inclined shaft construction. Lining, slagging, transportation, ventilation, drainage and other functions and a complete set of inclined shaft construction equipment. The equipment has two modes, shield and TBM, which will better meet the needs of engineering construction. Innovation: With open TBM and closed EPB two excavation modes, it integrates various functions such as excavation, slag, lining, filling, ventilation and sewage, and has a fast mode conversion technology. Through the theoretical calculation of the CSM model of the hob breaking rock force, the matching relationship between the key parameters of the double-mode shield in the inclined shaft of Xinjie Coal Mine was predicted, which provided a reference for the shield construction. The shield inclined well classification and flow gradient gradient slope drainage technology are proposed, and the selection and configuration of drainage system equipment are completed. Performance: Compared with traditional coal mine construction methods, TBM inclined wells are safe, fast, high quality and environmentally friendly. The world's first large-diameter mine inclined well TBM independently developed by Tiejian Heavy Industry has filled the application gap of the full-section tunnel boring machine in the construction of inclined shaft in coal mines, marking a major breakthrough in the collaborative innovation of large-scale high-end equipment manufacturing in China. Equipment users: China Railway Construction Bridge Bureau, China Railway 11th Bureau |