Changsha office 0731-88922097

Zhuzhou office 0731-22867780

DETAILSPAGEProduct CenterTechnical SolutionProject Case |

ParticularsLanzhou Water Source Construction Project III Standard Double Shield Rock Tunnel Boring Machine (TBM

Features: - Advance drilling, advanced support, direct observation of changes in the lithology of the cave wall, is conducive to geological map depiction. - The cutter head adopts Hardox board, chrome carbide composite wear plate and peripheral hard alloy block with high wear resistance and long service life; - The main drive adopts imported double row cylindrical roller thrust bearing, which has long life and high safety factor; - Reliable and efficient PLC control system, real-time online monitoring and data acquisition. - Innovative multi-variety material conveying system, safe and efficient transportation of segments, filling materials and various construction consumables; - The mainframe structure and system layout meet the requirements for in-situ disassembly in the hole, and the equipment is easy to disassemble and transport; - Patented single-tube single-pump foam system with continuous adjustment of injection parameters and good system reliability.

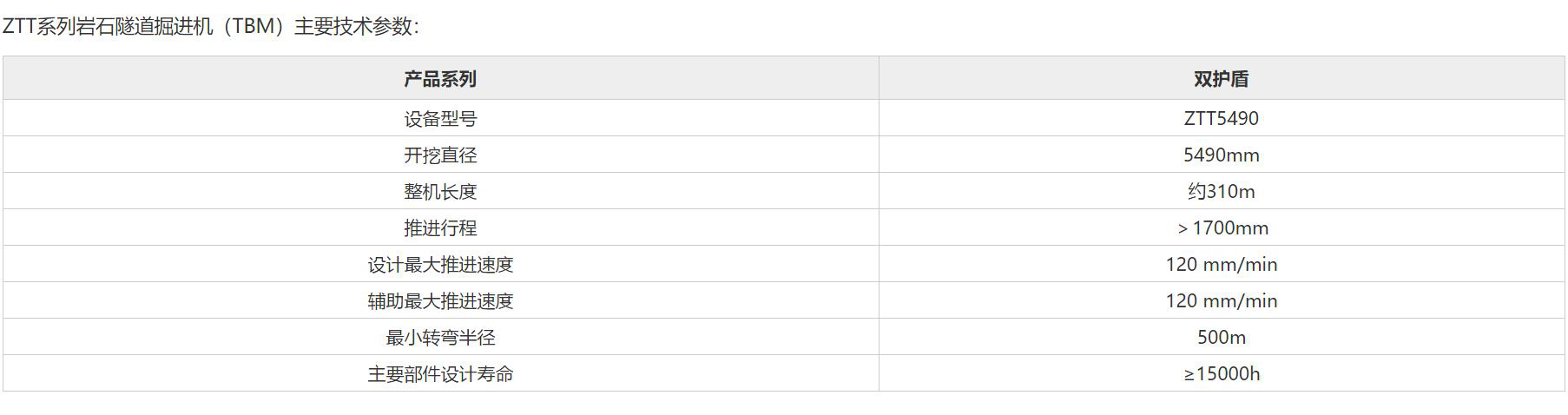

Project Name: Lanzhou Water Source Construction Project III (TBM2) Project Location: Lanzhou City, Linxia Prefecture Project Overview: The line area crosses the topography and landforms from the middle and low mountains to the loess source and Liangsong District. The highest elevation is about 2690m. It is located near the Taipingzhang of Chenjing Township, with a minimum elevation of about 1600m. It is located near the Pengjiaping Water Plant. The valleys of the line area develop and cross two large rivers, the Yellow River and the Weihe River, and the valleys tend to intersect at a large angle with the line. The planned length of the project route is about 14km. The terrain and terrain are from the middle and low mountains to the loess source and the Liangzhu area. The construction site is mainly III and IV. The compressive strength of the rock is 15~75MPa and the maximum buried depth is 954m. There is a relatively stable section of the rock mass in the long section of the construction line, but there is a fault zone. The length of each fault zone is about 50m, and the risk of water inrush and mud is higher. Difficulties in the project: the construction distance is long, the rock hardness is high, the stratum along the line is variable, and the buried depth, water inrush, rock burst, geothermal and other tunneling difficulties are difficult to construct. Equipment type and parameters: ZTT5490 double shield rock tunnel boring machine, excavation diameter 5.49m, total length nearly 318m, including 12m long mainframe and 25-carriage rear distribution system, the total weight of the equipment is 1250t, the total installed power is about 3400kw, the maximum tunneling speed can reach 120mm/min. Innovative point: it has the same cutterhead, slag discharge system and support device as the open TBM, and has a shield body, a tube assembly mechanism and a propulsion system similar to the shield machine. It is especially suitable for the surrounding rock crushing and poor stability. Rock formation conditions. It has three opening modes: open type, single shield type and double shield type. It can flexibly select different driving modes according to geological conditions and construction schedule. Especially in the double shield mode, the two sets of propulsion systems are alternately arranged. Work, can achieve continuous uninterrupted tunneling of TBM, with high tunneling speed. Performance: It took only 4 months for Tiejian Heavy Industry to complete the design, manufacture and acceptance of TBM equipment with quality and quantity. It is usually about 8 months ahead of the international similar equipment. The industry practice of the development cycle of similar products. The equipment began to excavate in February 2016, opening a 14km mountain rock drilling trip. |